Screen printing machine Introduction

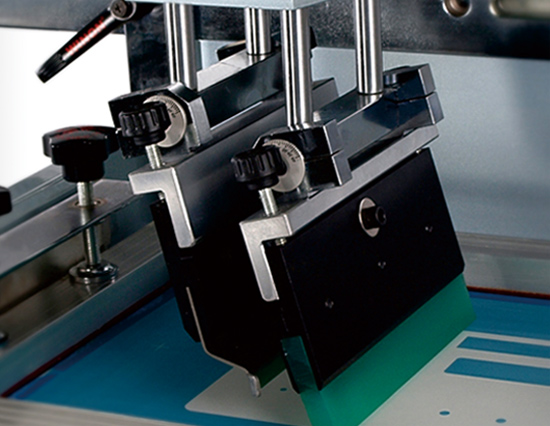

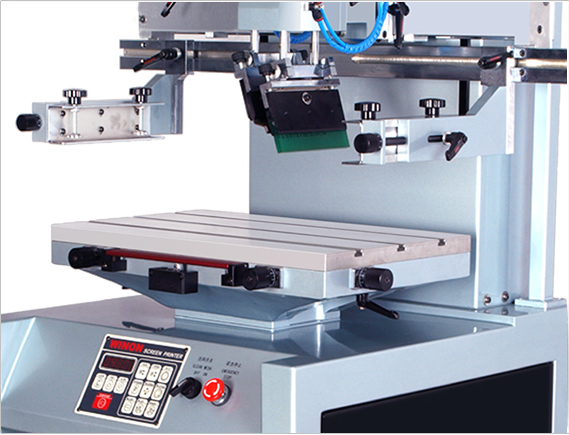

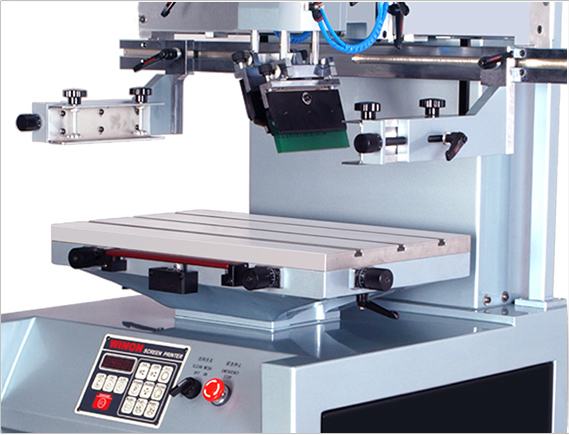

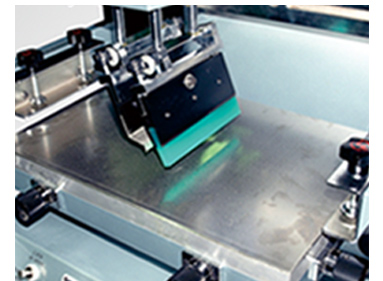

Screen printers are the machines to print images or words onto flat or regular curve surfaces. Below is their working principle: screen plate is developed with the photosensitive material, pinholed in the image place and the rest screen holes blocked up. Then the screen plate is mounted onto the machine, the squeegee doctor blades the ink onto the workpieces just as the image shows,and printing process is finished.

With the characteristics of easy operation, screen printing can be widely applied in such industries as textile printing, electronics,arts,decoration, and publishing.

| Screen plate up/down | |

| Stroke | Model |

| 260 | WSC-260 |

| 350 | WSC-350 |

| 500 | WSC-500A,500B |

| 600 | WSC-600 |

| 700 | WSC-700 |

| 1000 | WSC-1000 |

| 1500 | WSC-1500 |

| Worktable up/down | |

| Stroke | Model |

| 360 | WSC-360 |

| 500 | WSC-500C,500AB |

| 650 | WSC-650 |

| 1200 | WSC-1200 |

Stroke: 360 ~500mm

Applied to print on materials like membrane keyboard and pressure sensitive label.

Stroke: 500 ~700mm

Applied to print on ceramic, glazing product, electronic circuit board, glass, metal , pressure sensitive label.

Stroke:700mm or above

Applied to print on work pieces of large area like plastics, hardware accessories, toys, outdoor advertising boards, food packaging, etc.

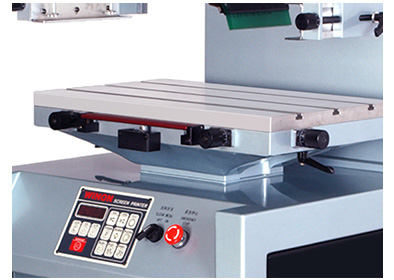

Screen plate up/down, light and compact;

microcomputer control, multi-function, easy operation; world-famous pneumatic components power, durable and solid; worktable and screen arm microadjustable, easy commissioning; gear and rack convey cooperatively with a suitable fixture, precise

printing positioning; special shock absorber, stable performance; mesh clean and replace is convenient with printing head up device (some types) avoid mesh sticking after printing with screen plate up device (some types)

it can be widely applied in the industry of textile printing, electronics, arts, decoration, publishing, and so on.

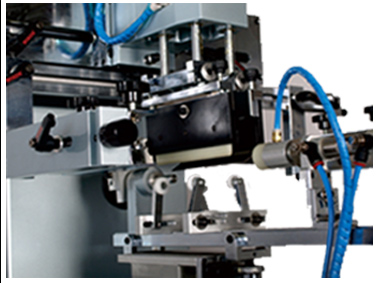

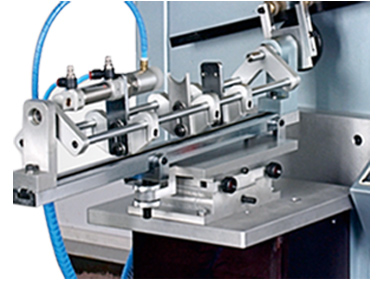

Widely applied to printing on round or curve workpieces such as cups, electric products, cosmetic containers, pen arms, toys, bottles, etc.

The characteristics of curve screen printer Microcomputer control, multi-function, easy operation; world-famous pneumatic components power, durable and solid; worktable and screen arm microadjustable, easy commissioning; gear and rack convey cooperatively with a suitable fixture, precise printing positioning; special shock absorber, stable performance; widely apply to print various kinds of curve surfaces of columnar, conic, oval cup, bottle, tube, can.

| A | Work for round printing |

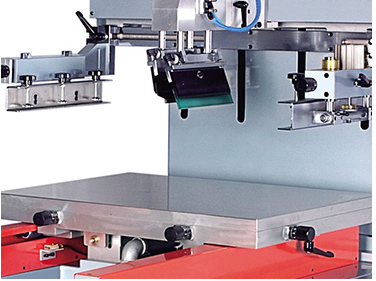

| B | Worktable for flat Printing |

| C | Worktable for oval printing |

| D | Worktable Front and Rear |

| E | EPRECISION guide Rail |

| F | Worktable Up and Down |

| M | Electric Screw Drive |

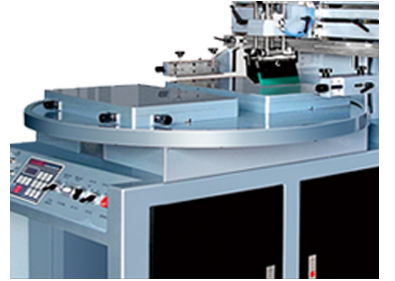

| R# | Index worktable |

| V | Vacuum and Suction Worktable |

|

|

|

| A Worktable for round printing | B Worktable for flat Printing | C Worktable for oval printing |

|

|

|

| D Worktable Front and Rear Movement | E Precision Guide Rail(e.g. WSC-500BE) | Worktable Up and Down(e.g. WSC-500FB) |

|

|

|

| M Electric Screw Drive | R Index worktable(e.g. WSC-500BR) | V Vacuum and Suction Worktable(e.g. WSC-500BV) |

Webpage